Група компаній МІДІЕЛ – MIDIEL Group

Провідний виробник шахтних підйомних машин, вентиляторів головного провітрювання та мобільного підйомного прохідницького обладнання

У 2023 році компанія (торгова марка) «МІДІЕЛ» відзначає своє 30-річчя. Після відкриття у 2004 році європейського представництва в особі «Midiel AB» (Швеція) утворилася Група компаній «МІДІЕЛ», яка позиціонує на ринку як системний інтегратор обладнання шахтних підйомних установок. Також у сферу діяльності ГК «МІДІЕЛ» входить обладнання для проходки вертикальних стволів (мобільні прохідницькі підйомні машини та прохідницькі лебідки), аварійно – рятувальні і аварійно – ремонтні пересувні машини та вентилятори головного провітрювання копалень та шахт. ГК «МІДІЕЛ» увібрала багаторічний досвід проектування та виробництва даного обладнання підприємствами України, а також сучасні технології європейських виробників. До складу ГК «МІДІЕЛ» входять такі компанії:

ТОВ «Мідіел МЕ» (Харків, Україна)

ТОВ НВФ «Мідіел» (Харків, Україна)

«Midiel AB» (Гетеборг, Швеція)

«Midiel Balkani Ltd» (Пловдив, Болгарія)

«Midiel Engineering AG» (Швейцарія)

«Midiel AB IS» (Гонконг)

Стаціонарні підйомні установки

ГК «МІДІЕЛ» проектує та комплектно постачає наступні види стаціонарних підйомних машин індивідуального виробництва:

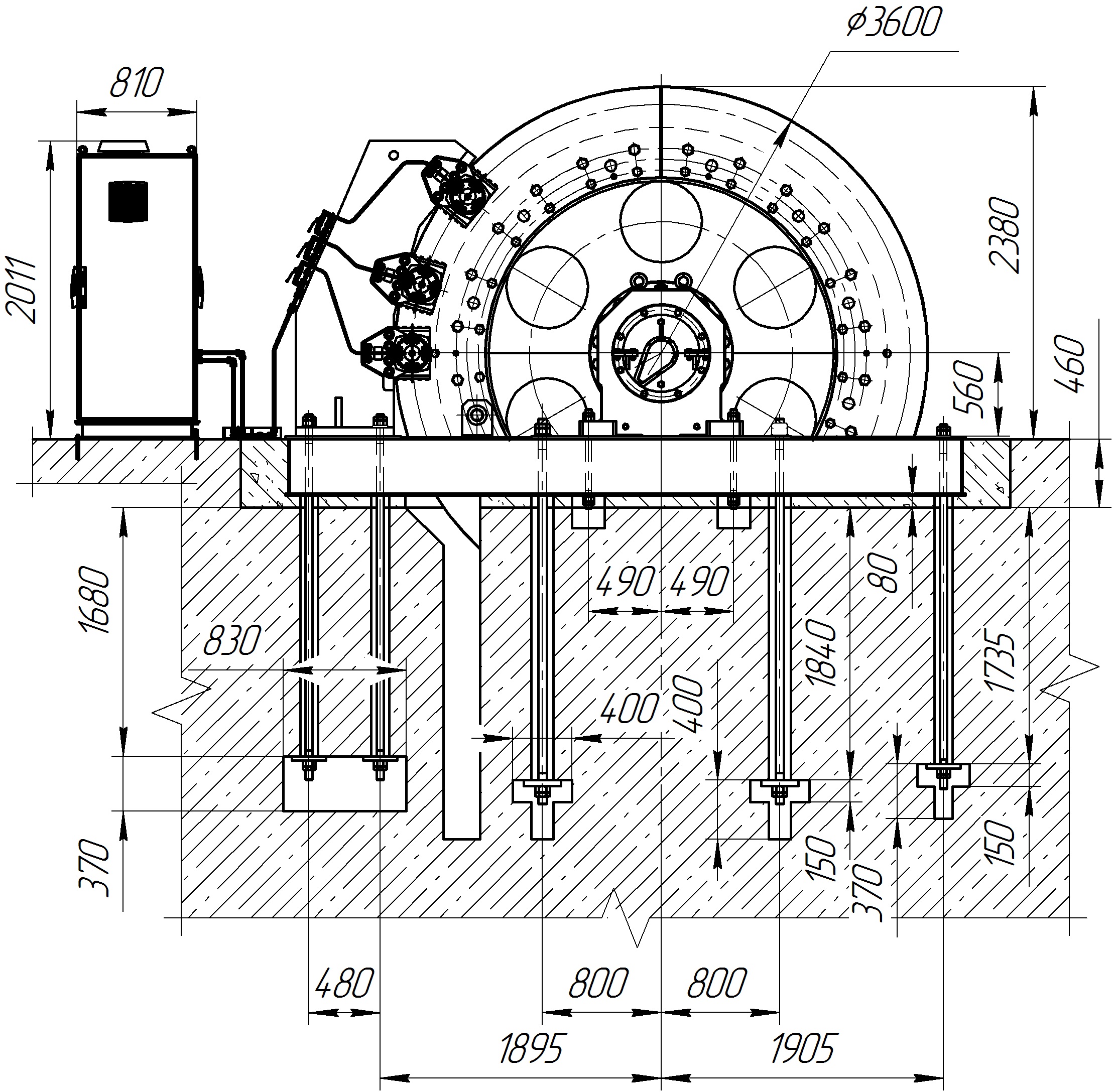

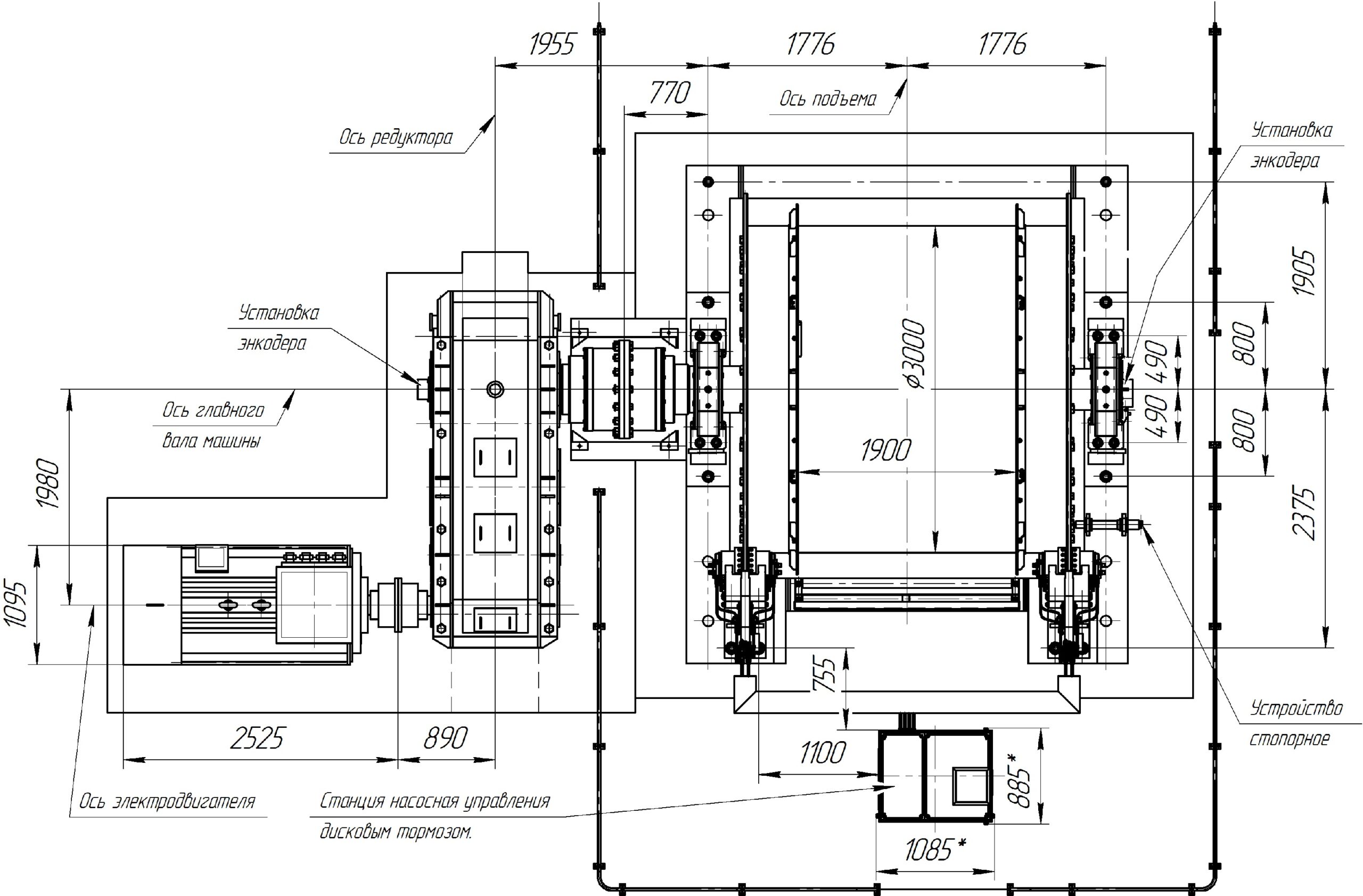

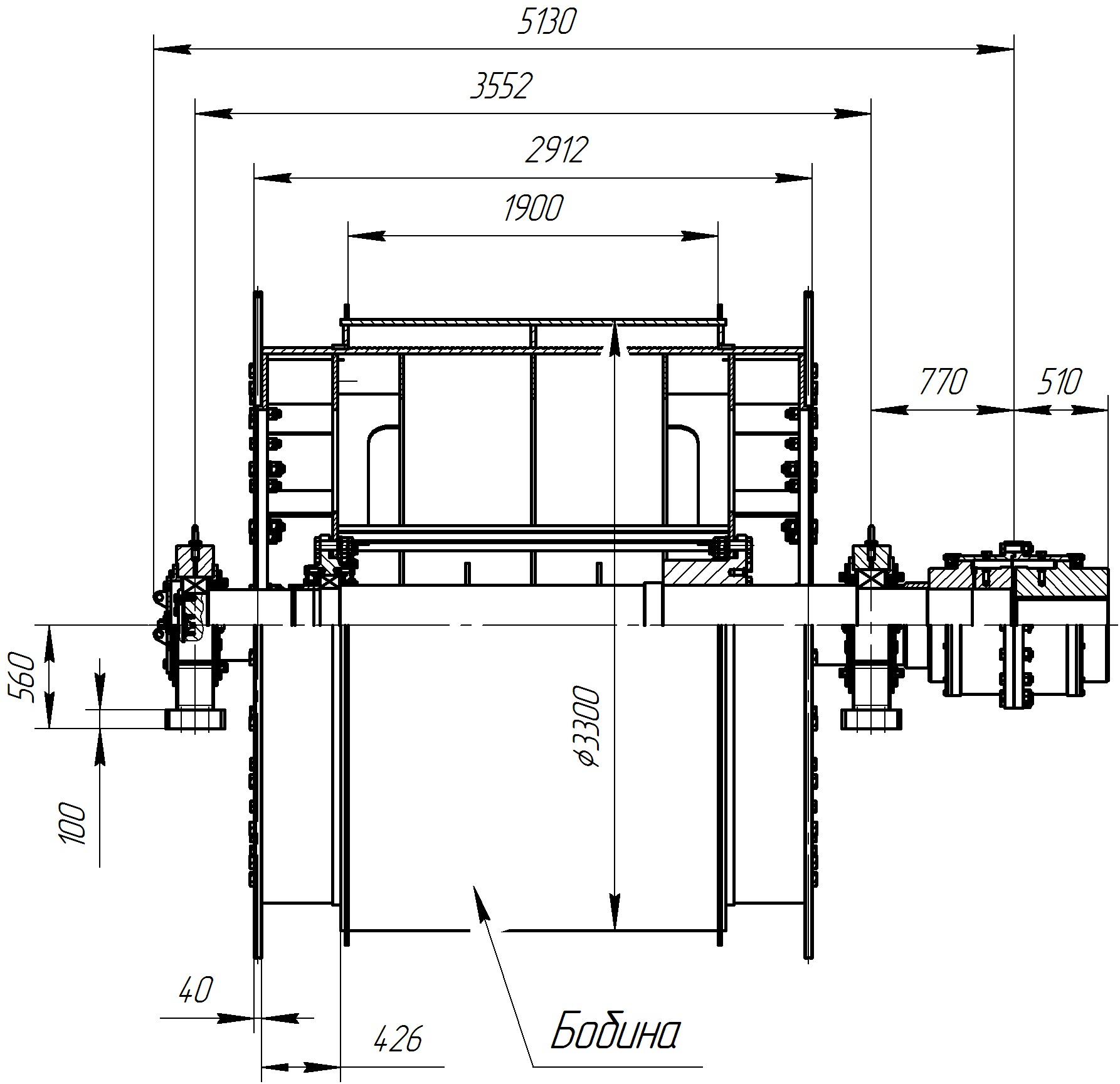

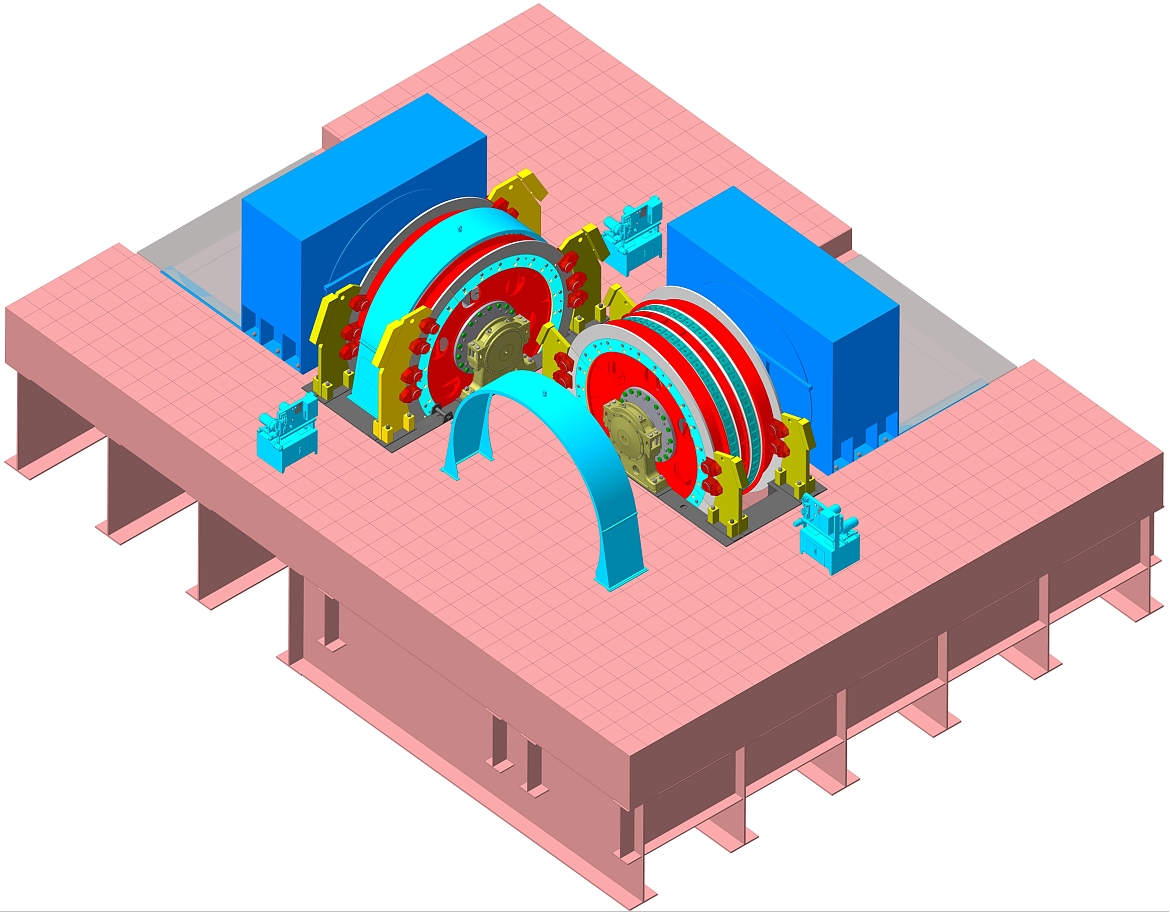

1. Барабанні підйомні машини наземного та підземного (вибухозахищеного) виконання:

- однобарабанні, в тому числі з розрізним барабаном з діаметром барабана від 1,6 м до 6,3 м;

- двобарабанні з діаметром барабана від 3 м до 6,3 м.

2. Багатоканатні підйомні машини (з шківом тертя) баштового та наземного розташування з діаметром шківа від 2,1 м до 5 м.

Детальніше

Обладнання для проходки вертикальних стволів

Мобільні прохідницькі машини застосовуються як однокінцеві підйомні установки. Загалом призначені для підйому та спуску людей та вантажів в баддях та клітях при проходженні вертикальних стволів. Подекуди вирішують задачі підйому та спуску людей та вантажів при виконанні аварійних, ремонтних та інспекторських робіт у вертикальних стволах. Прохідницькі лебідки є основним засобом для підвіски, спуску та підйому прохідницьких полків, опалубок, насосів, направляючих канатів, трубопроводів, кабелів та іншого прохідницького і гірничошахтного обладнання при прохідці, заглибленні, армуванні та ремонті вертикальних стволів шахт.

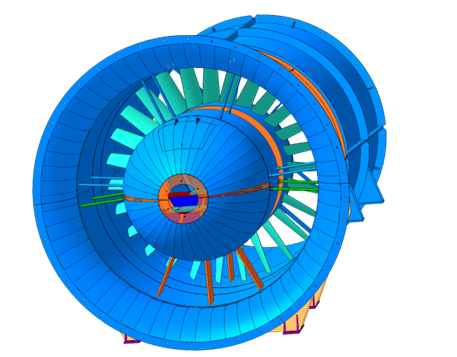

ДетальнішеВентилятори головного провітрювання

Фахівцями ГК «МІДІЕЛ» розроблено серію одноступінчастих осьових вентиляторів ВО. Вентилятори даної серії призначені для установок головного провітрювання шахт і рудників гірничодобувної промисловості, і можуть застосовуватись у вентиляційних системах підприємств металургійної, хімічної і інших галузей промисловості. Типорозмірний ряд вентиляторів містить нереверсивні вентилятори типу ВО-18ВК, ВО-21-ВК, ВО-24ВК, ВО-30ВК, ВО-35ВК, ВО-40ВК, ВО-50ВК і реверсивні вентилятори тих самих типорозмірів із діаметром робочого колеса від 1800 до 5000 мм.

Детальніше

Технологія заміни великих підйомних машин

ГК «МІДІЕЛ» пропонує заміну великих підйомних машин з мінімальним простоєм підприємства.

ДетальнішеМашина підйомна аварійно-ремонтна МПАР-63-1000Д

Для підйому та спуску людей, вантажів при виконанні аварійних та ремонтних робіт у вертикальних стволах ГК «МІДІЕЛ» пропонує машину підйомну аварійно-ремонтну МПАР-63-1000Д.

Детальніше